Manufactured from high quality chromium nickel stainless steel, PowerCoil wire thread inserts provide high strength internal threads that resist the effects of temperature and corrosion. Their unique design ensures superior threads whose compound performance cannot be reproduced by any other single fastening method. Available in two basic forms, free running or screw locking, they are much lighter and less expensive than any other equivalent type of thread insert and because of their compact size they can generally be incorporated into existing designs where no previous provision has been made.

Features & Benefits

For many years, helically coiled wire thread inserts have been vastly underestimated. The popular misconception that they were designed for the repair of damaged threads has given this unique fastener a false image. They are much lighter and less expensive than any other equivalent type of thread insert and because of their compact size, can generally be introduced into existing designs where no previous provision has been made. Unlike many other economic measures, their introduction increases quality and performance whilst reducing overall product cost. Their introduction may result in the use of thinner sections or ligh

ter parent materials without sacrificing thread strength.

They protect tapped threads against failures due to stripping, seizing, corrosion and wear. PowerCoil wire thread inserts are produced from austenitic stainless steel wire which is work hardened to a tensile strength above 200,000psi and a hardness of rc43-50. The inserts have an exceedingly smooth surface finish that virtually eliminates friction-induced thread erosion.

The continuous helically coiled design negates the need for thick wall structures to support the internal and external threads – the diamond profile wire coil is the thread. PowerCoil wire thread inserts can be installed in reduced size bosses or flanges and within constricted areas – saving space and weight while providing high strength.

A boss radius equal to the nominal

bolt diameter is usually sufficient.

A complete range of installation tools are available to suit specific production techniques. A range of hand tools exist for small runs and repairs; electric and pneumatic tools are available for high volume production requirements.

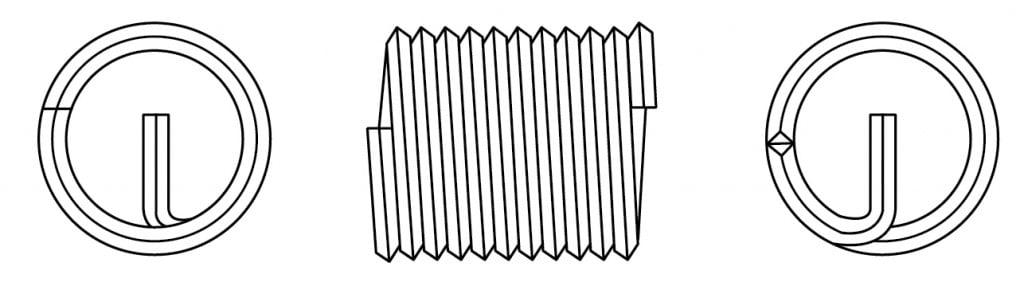

Free Running

Produced from precision profiled austenitic stainless steel wire wound into a helical spiral, PowerCoil free running inserts have a spring like appearance. When installed, using any one of a variety of manual or automatic tools, they provide strong permanent internal threads which resist heat and corrosion. Once fitted, their position is maintained by the action of radial pressure between their coils and the flanks of the tapped hole. This pressure exists because their free diameter is larger by a calculated amount, than their installed diameter.

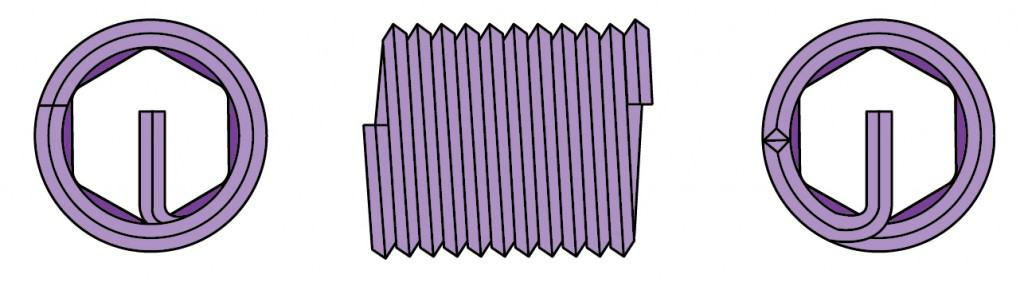

Screw Locking

Screw locking (or prevailing torque) inserts are of particular value in applications subject to the effects of cyclic vibration or impact. In addition to the benefits afforded by free running inserts, PowerCoil screw locking inserts offer the additional security of prevailing locking torque. This is achieved by the action of one or more polygonal grip coils positioned within the insert’s length, which exert radial pressure on the male thread. Each grip coil consists of a number of tangential locking chords which protrude inside the minor diameter of the normal free running coils. As the male thread passes through these grip coils, the locking flats are displaced thus exerting radial pressure or prevailing torque on the male thread. On removal of the male thread, the locking coils relax to their original form permitting repeated assembly whilst retaining a measurable level of prevailing torque.

Note: It is recommended that only close fit plated or lubricated bolts or screws are used with screw locking inserts.

In a future article we will explore other inherent benefits of wire thread inserts, particularly strength, wear resistance, and corrosion protection.

Comments are closed.