Silbertool Rolling Process

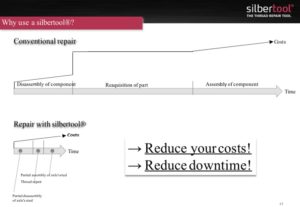

While working on any type of mechanical component it is only a matter of time before you struggle with a damaged thread. In many cases a damaged thread will require a replacement of the entire component.

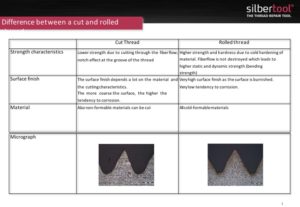

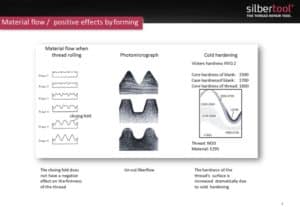

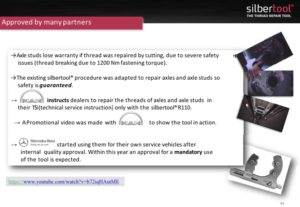

Preserving the original shape of the thread is cruicial for the safety of the mechanical components. That’s why using a technology which removes material and weakens the thread can be dangerous.

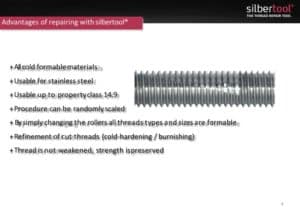

Silbertool uses the first non – cutting external thread repair technology in the world and repairs the thread by forming it back to its original geometry.

Moreover the static and dynamic strengths are restored completely, the surface of the thread is hardened by cold hardening and the original parts are preserved.

Silbertool Rolling Process works on any external thread!

1. The required rollers are mounted in the tool which is then placed next to the damaged part.

2. The Silbertool is tightened up and manually rotated around the work piece to restore the thread completely.

The Material Testing Institute Hanover has proven that a thread repaired with Silbertool shows an even higher fatigue endurance limit than a new thread.

Silbertool has been thoroughly tested on threads up to 1400N/mm², the equivalent of grade 14.9, roughly equal to a hardness of 44HRC. The Rollers themselves are hardened up to 56+4HRC, which is equal to a tensile strength of 2100-2300 N/mm². Therefore, the rollers can effectively form material up to that hardness.

Galvanic zinc coating of a thread has a hardness of about 100HV. The tool can easily handle the hardness of the coating; however, the zinc coating will likely crack due to its brittleness. We recommend using a zinc spray to cover the repaired threads after rolling.

Repair safe and easy with Silbertool® The thread repair tool!

Comments are closed.